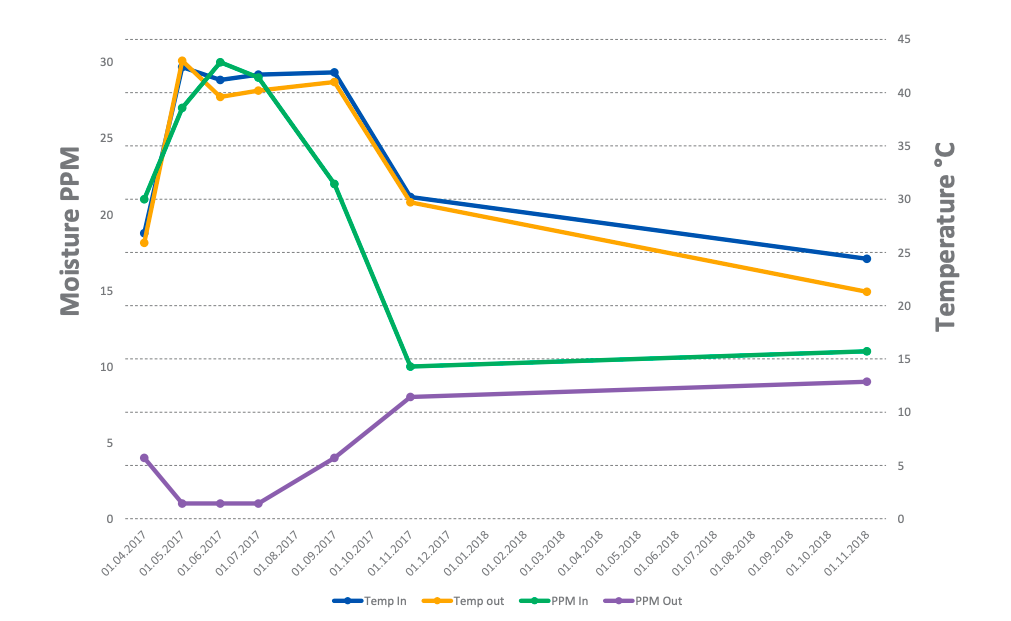

- Continuous monitoring of oil temperature and moisture content entering and exiting the TRANSEC unit

- Increases life expectancy of transformers by drying the insulation paper

- Maintain a safe transformer with high breakdown voltage

- Online installation & operation – no shutdown

- Cost effective solution – 24/7 continuous drying and monitoring

- No operator required. Stand alone unit LV powered

Function

TRANSEC is a system to monitor and extract the moisture in power transformers of all sizes. The problem of wet transformer is already well known. Due to high temperatures, moisture and oxygen, the insulation paper within the transformer is degrading. One of the by-products resulting from this chemical reaction is molecules of water (H2O). While only a small part of the moisture is dissolved in the transformer oil, more than 98% of the moisture becomes diffused in the tons of insulation paper. Depending on the percentage of moisture, the aging of the transformer increases faster and the breakdown voltage decreases. This can lead to failures such as flashovers between the windings. Oil temperature changes during the operation even increase the risk of an outage.

Once the oil in the transformer gets dried by TRANSEC, it dehumidifies the insulation paper, hence slowing the aging process. Using this cycle effect, TRANSEC keeps the oil and the insulation paper permanently dry, ensures a faultless operation, and elongates the life expectancy of the transformer significantly. Comparing to other solutions, the transformer can be dried during its operation. There is no need for a maintenance outage.

Operational Principle

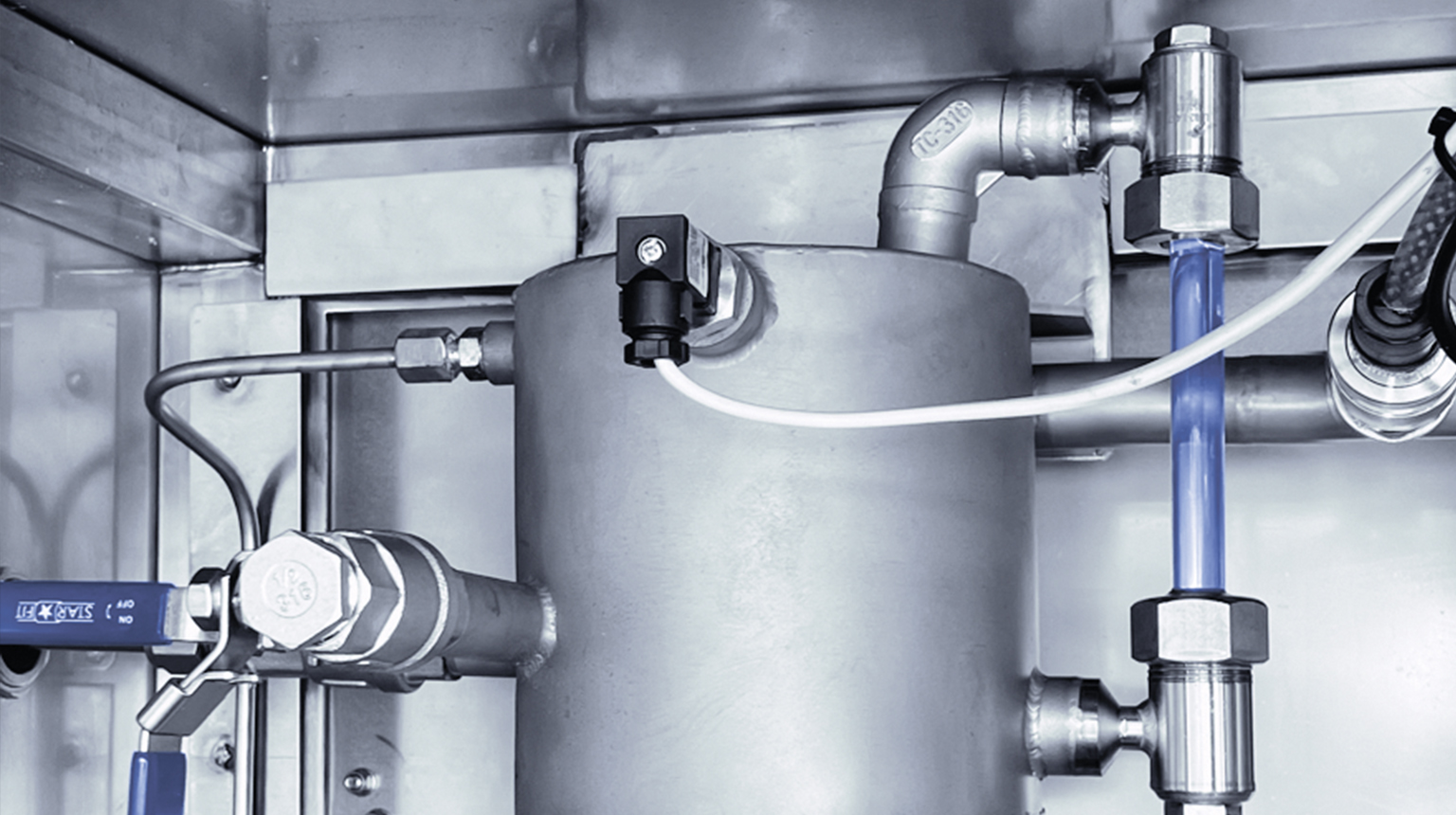

TRANSEC extracts moisture from the oil thanks to molecular sieves. An electrical pump circulates the transformer oil through the TRANSEC cylinders containing a large amount of these molecular sieves. The molecules of water dissolved in the oil will remain in the TRANSEC cylinders. Two moisture and temperature sensors are placed at the beginning and end of the system in order to monitor the moisture level of the transformer and to control a proper filtration process. Oil particles filtration and air bubble removal is also ensured during this cycle.

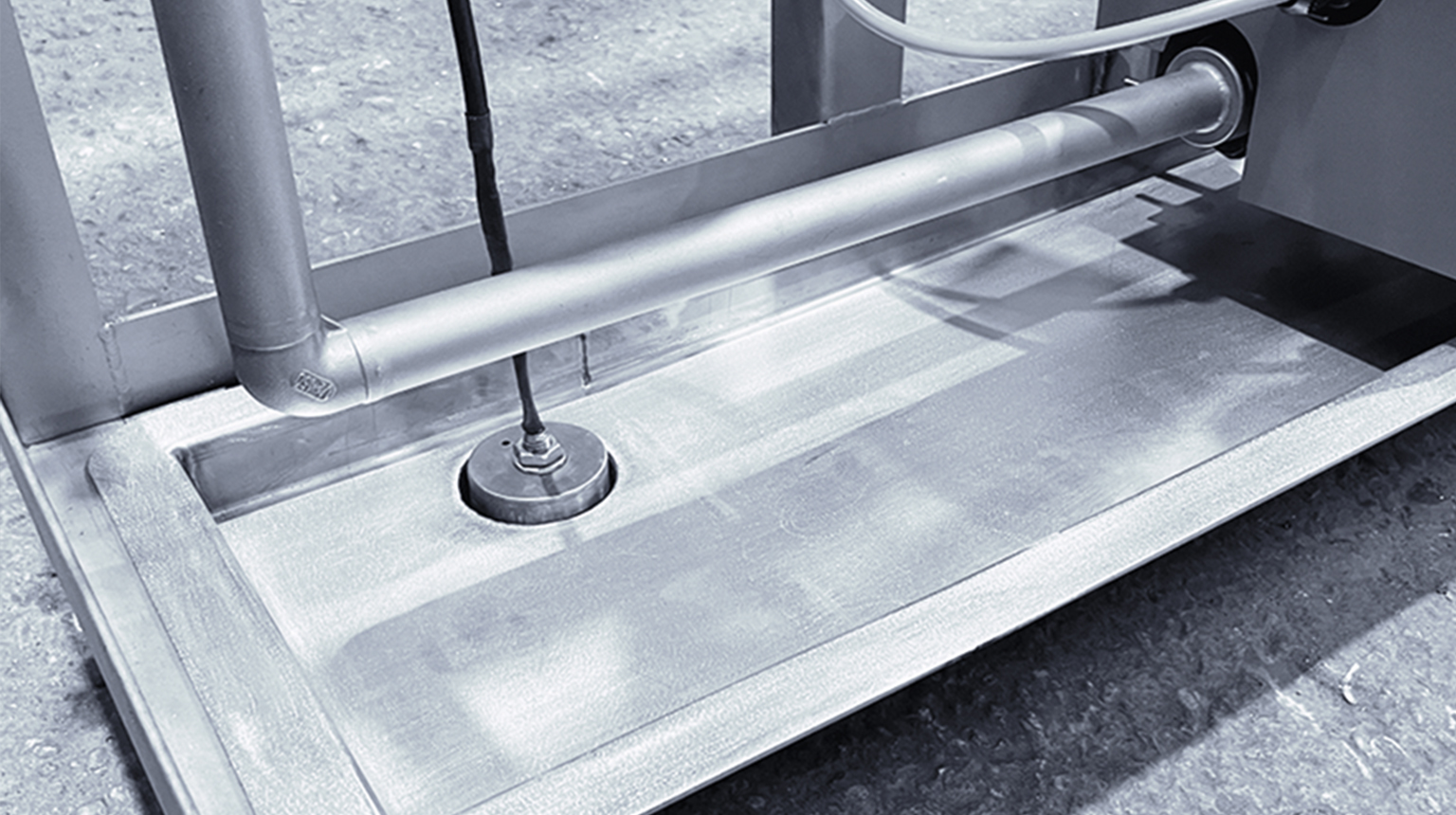

TRANSEC can either be mounted directly on the power transformer or can be installed on a stand-alone frame next to it. Two pipes are connected to the upper and lower valves of the transformer. Every TRANSEC unit includes sample/measuring points at the inlet and outlet.

Technical characteristics

CL1i, CL2i, CL3i TECHNICAL DATA|

Parameter |

CL1 |

CL2 |

CL3 |

|

Water extraction capacity before cylinder change |

3 to 4 litres |

6 to 8 litres |

10 to 12 litres |

|

Flow rate with Grundfos UPS2 pump |

70 to 90 litres per hour |

||

|

Flow rate with TC500 pump |

400 to 500 litres per hour |

||

|

Particle filter |

10 microns on inlet & outlet. Optionally the unit can be fitted with an additional 3 microns pre-filter. Optionally the unit can be fitted with an additional 5 microns pre-filter for heavily sludged transformers. |

||

|

Material |

Stainless steel 304 Grade |

||

|

Oil temperature range |

0°C to 105°C |

||

|

Acceptable environment condition |

-40°C to +60°C |

||

|

Altitude |

up to 2000 m |

||

|

Protection class of the unit enclosure |

IP55 |

||

|

Protection class of the MCC enclosure |

IP65 |

||

|

Power Supply |

240 V 50 Hz or 110V 60 Hz |

||

|

Pump Grundfos UPS2 Power |

140 W |

||

|

Pump Midland TC 500 Power |

250 W |

||

|

Number of cylinders |

1 |

2 |

3 |

|

Oil drying adsorbent |

zeolite with 3 Angstrom bead size |

||

|

Monitoring |

Available in option |

||

|

Size |

1940 x 1000 x 300 |

||

|

Installation weight without MCC |

128 kg |

164 kg |

200 kg |

|

MCC weight |

00 |

AMi |

WSi |

|

0.4 kg |

12 kg |

20 kg |

|

|

Installation time |

5 to 6 hours with 2 people |

||

|

Manufacturing type test |

3 bar pressure at 110°C for 1 hour |

||

|

Manufacturing routine test |

Cyclic 3 bar pressure at 60°C for 24 hours |

||

|

Enclosure |

Optional. In stainless steel |

||

|

Fixation |

On the wall or the ground |

||

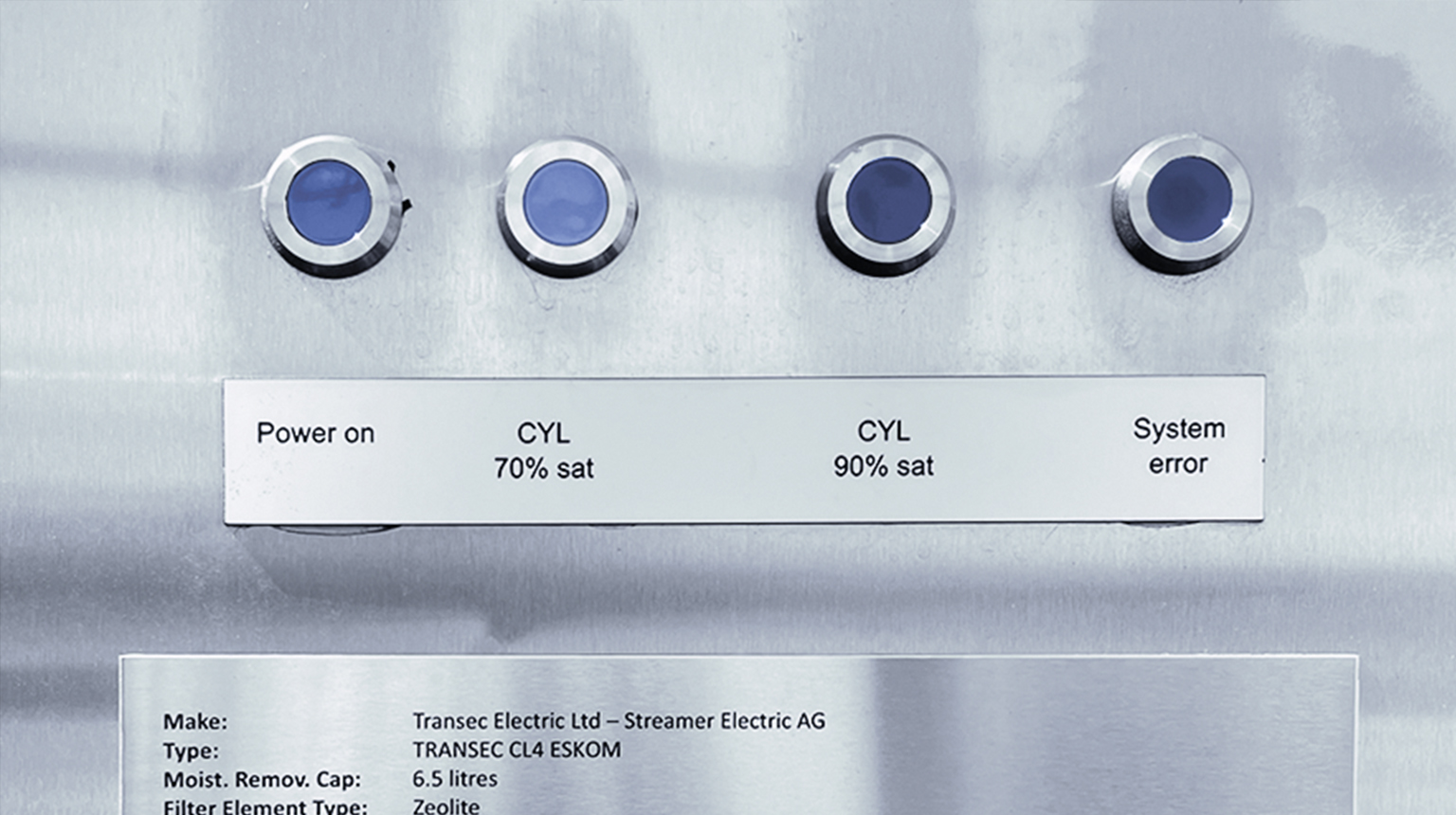

CL4 WSi TECHNICAL DATA

|

Parameter |

CL4 |

|

Water extraction capacity before cylinder change |

6.5 litres |

|

Flow rate with TC500 pump |

400 to 500 litres per hour |

|

Particle filter |

10 microns on inlet & outlet.

Optionally the unit can be fitted with an additional 3 microns pre-filter.

Optionally the unit can be fitted with an additional 5 microns pre-filter for heavily sludged transformers. |

|

Material |

Stainless steel 304 Grade |

|

Oil temperature range |

0°C to 105°C |

|

Acceptable environment condition |

-40°C to +60°C |

|

Altitude |

up to 2000 m |

|

Protection class of the unit enclosure |

IP56 |

|

Power Supply |

240 V 50 Hz |

|

Pump Midland TC 500 Power |

250 W |

|

Number of cylinders |

4 |

|

Oil drying adsorbent |

zeolite with 3 Angstrom bead size |

|

Monitoring |

WSi only |

|

Size |

1443 x 1200 x 747 |

|

Installation weight |

350 kg |

|

Installation time |

5 to 6 hours with 2 people |

|

Manufacturing type test |

3 bar pressure at 110°C for 1 hour |

|

Manufacturing routine test |

Cyclic 3 bar pressure at 60°C for 24 hours |

|

Enclosure |

304 Grade Stainless steel |

|

Fixation |

Self-standing |

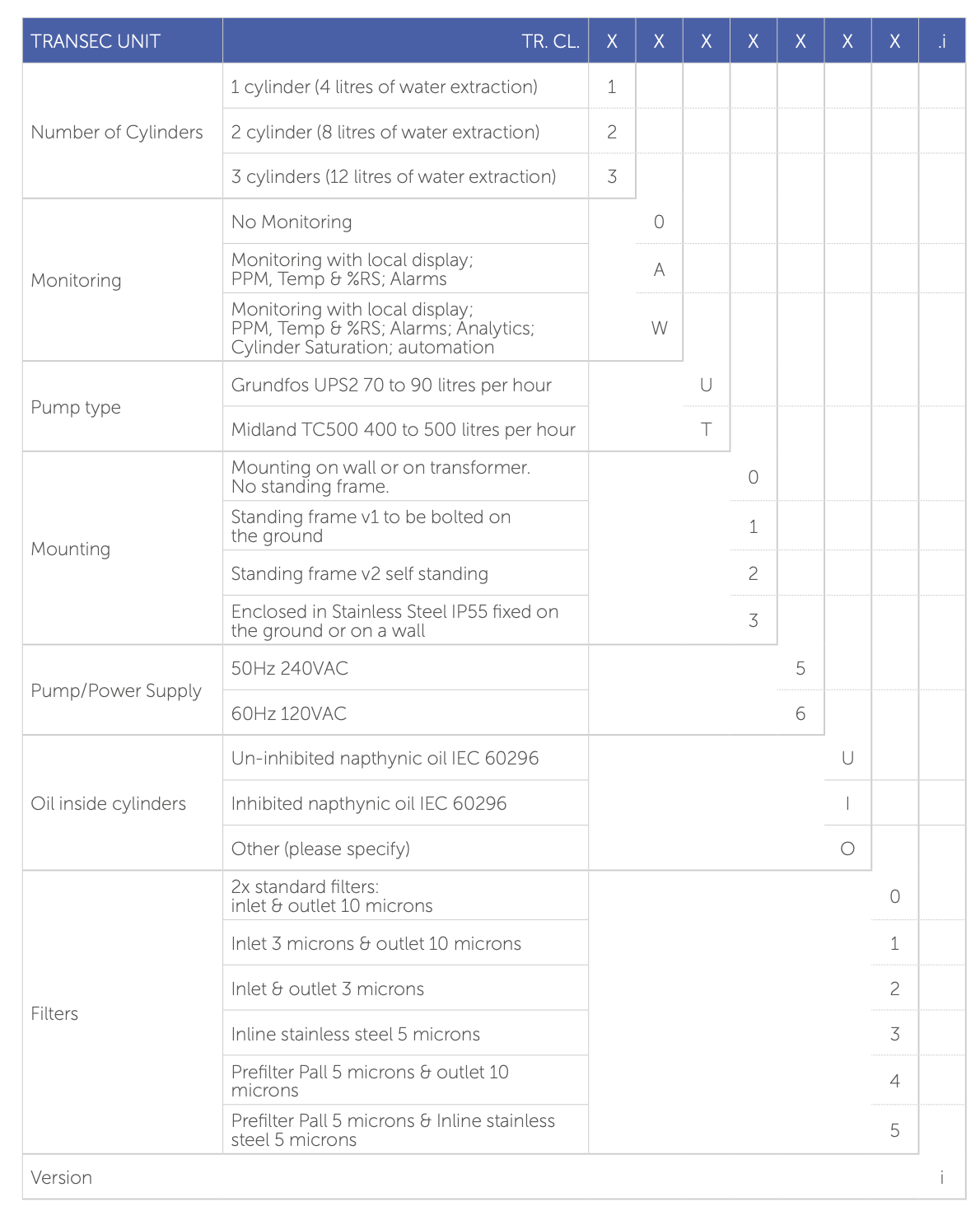

Product Selection guide

CL1i, CL2i, CL3i

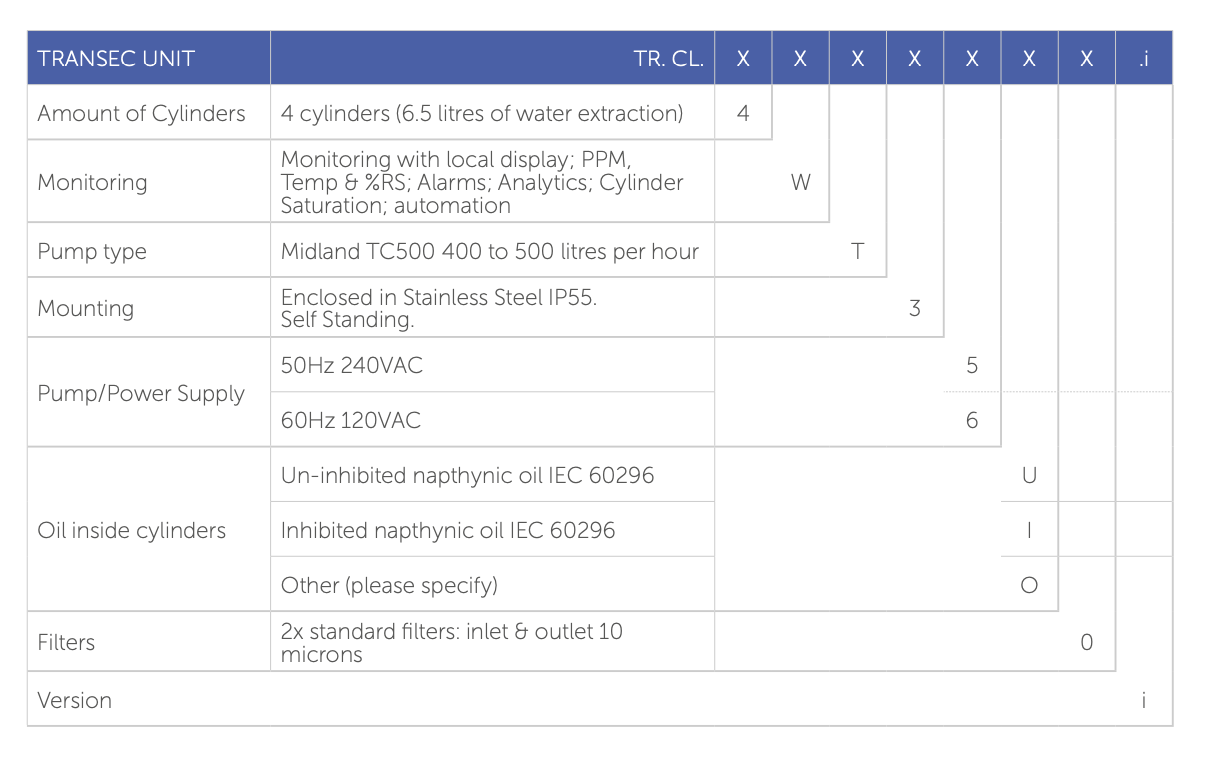

CL4i

Continuous moisture assessment with the TRANSEC monitoring

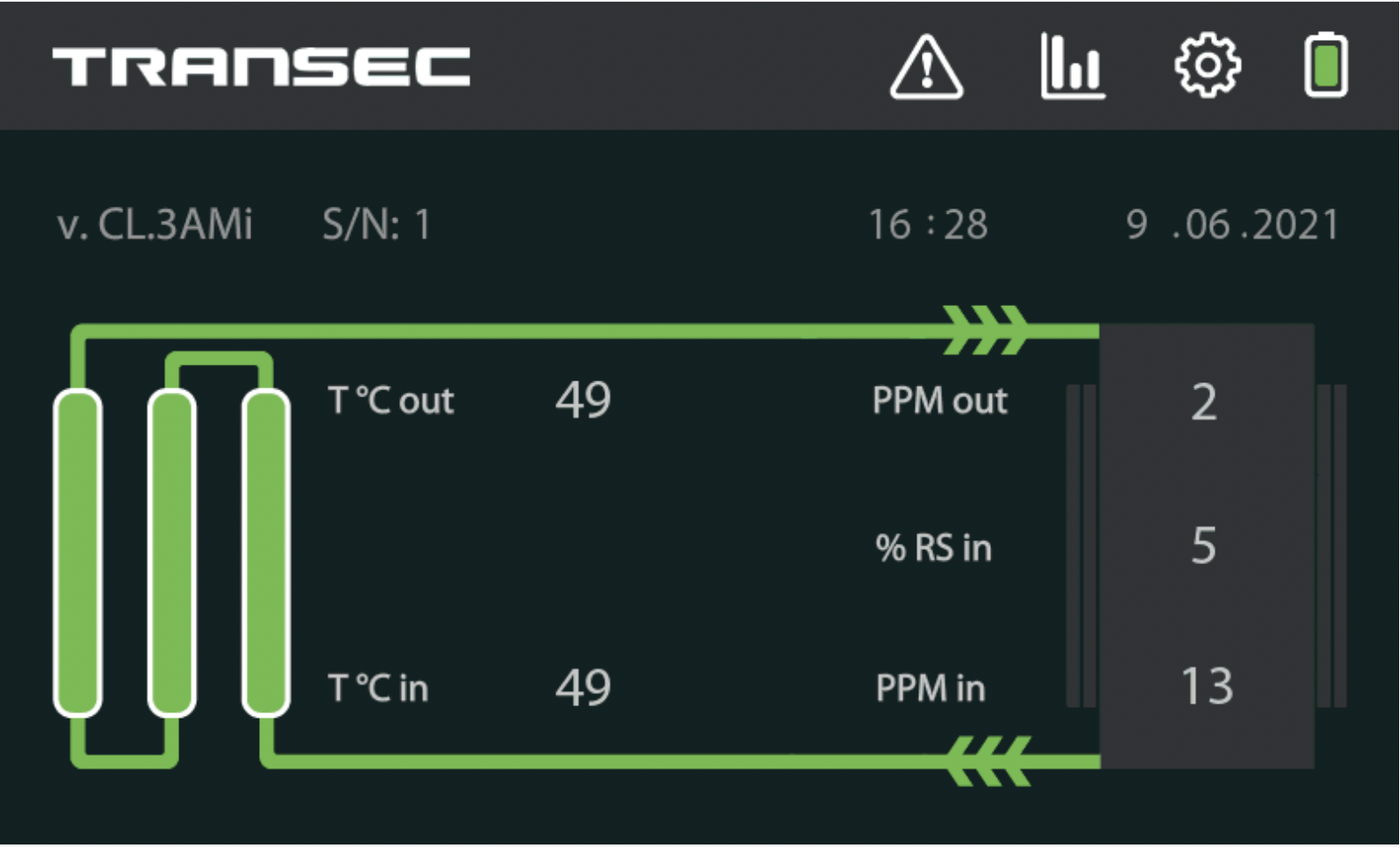

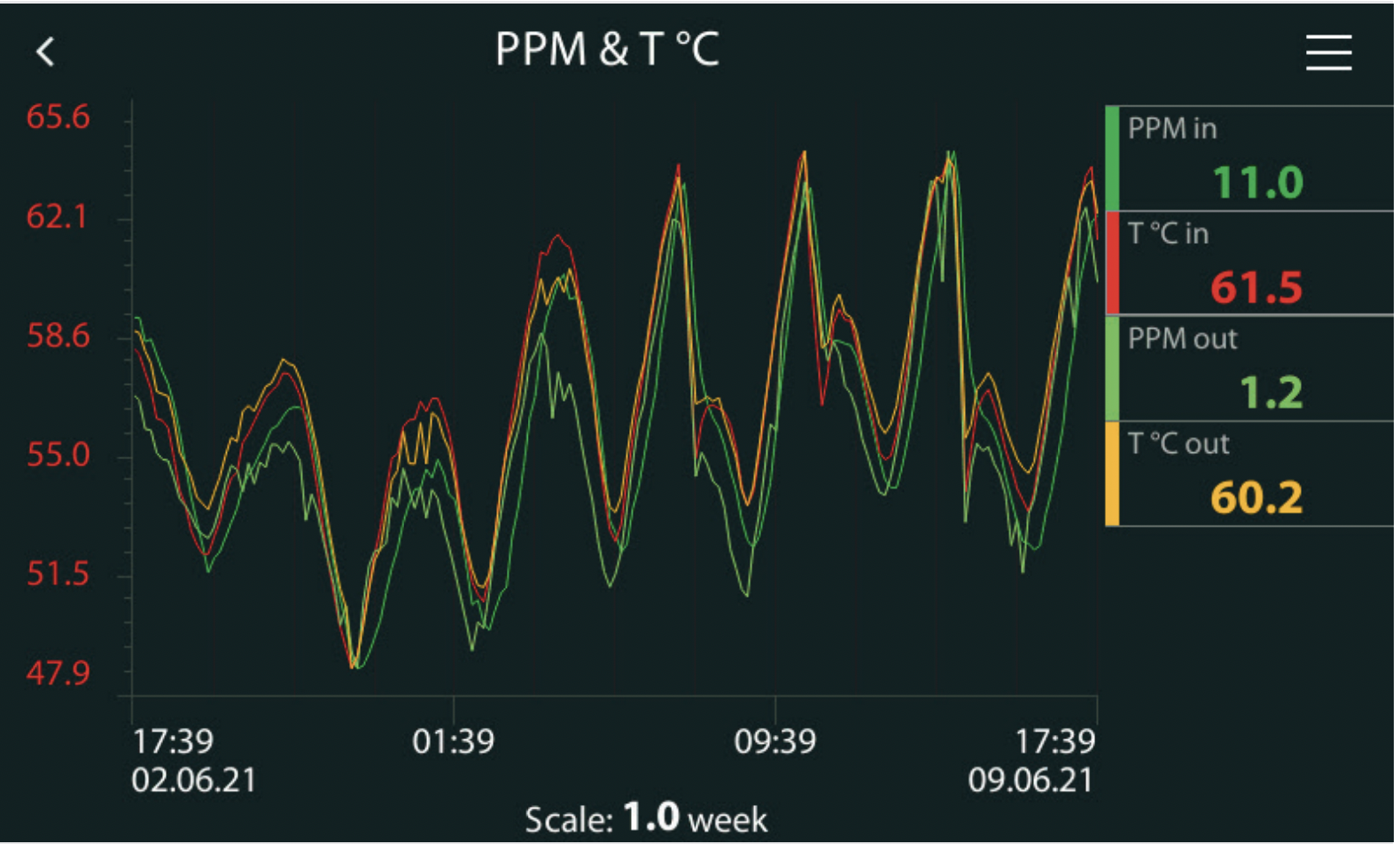

Monitoring cabinet AMiThe AMi TRANSEC monitoring cabinet continuously monitors the temperature and moisture dissolved in the oil entering and exiting the TRANSEC. This allows monitoring the good water extraction for the TRANSEC but also the moisture level of the transformer. Alarms can be set, and reports of all data collected can be downloaded.

Picture of HMI |

PPM and temperature trends on the AMi HMI |

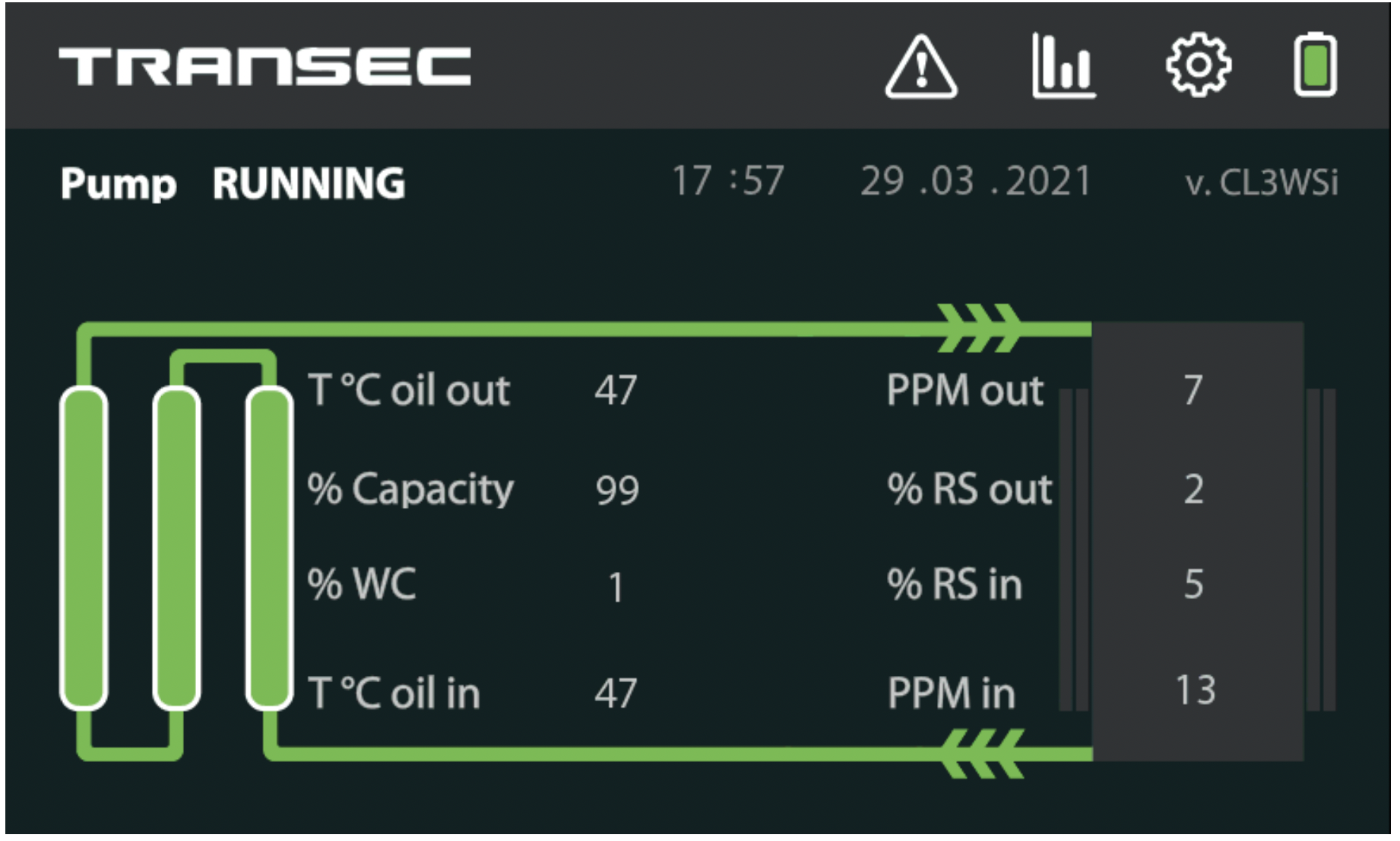

Monitoring cabinet WSI

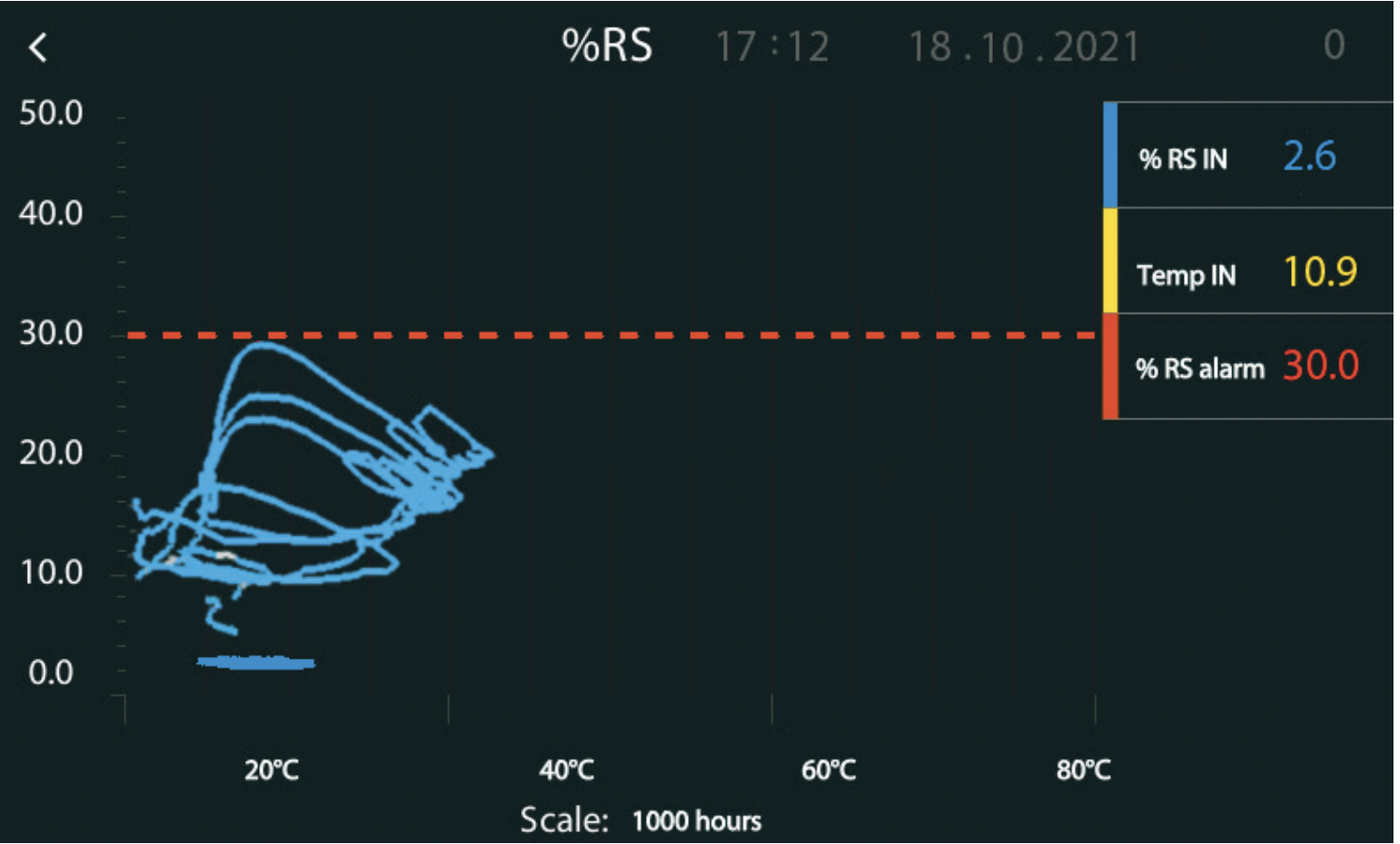

The WSi TRANSEC monitoring cabinet provides continuous monitoring of the temperature and the moisture dissolved in the oil entering and exiting the TRANSEC and allows to take action on it. The pump can be stopped under certain conditions. Also, other analyses are provided which will help to better understand the current moisture situation of the transformer and to take action.

Picture of HMI |

Relative Saturation versus temperature hysteresis graph |

Options available with TRANSEC

External enclosure|

The optional enclosure for the TRANSEC unit will protect the HMI and the hardware from rain, dust, heat from direct sunlight and UV. The enclosure is made of stainless steel. |

|

|

Monitoring and Control cabinet can be equipped with a gateway that allows to use fiber connectors for the Ethernet port. |

|

|

The accessory (only available on the WSi version) will detect any oil leak within the TRANSEC system and will provide the alarm accordingly. It is, of course, strongly advised to combine this option with an external enclosure (to protect from rain) and a solenoid inflow valve in order to block the oil circulation in case of leakage. |

|

Inflow controllable solenoid valve

|

This valve can be set remotely to operate and block the oil flow in case of leakage or rising temperature. |

|

Deaerator glass gauge and switch

|

To be sure that no air is entering the transformer, a deaerator is placed at the end of the TRANSEC. For additional protection, it is possible to see the level of air in the deaerator with an optional glass gauge and to have a switch that will signal an alarm if the level of air reaches a dangerous level. |

|

|

They will allow you to observe: - Power on — unit is working - CYL 70% sat — cylinders have been saturated up to 70% - CYL 90% sat — cylinders have been saturated up to 90% - System error — there is a system error that you will see on the HMI screen. |

|

What to do when the moisture extraction cylinders are saturated?

The first thing to do is to contact your local representative of Streamer Electric AG. Streamer make an effort to find companies close to you to support you efficiently. Local representatives have a stock of ready cylinders which they can provide to you. The most convenient way to contact us is through the website.

TRANSEC units can typically extract between 3 to 4 litres of water per cylinder before saturation. The rate of extraction is directly linked to the amount of water available in the transformer. The higher the moisture content and the warmer the oil is, the faster the extraction will be. You can find the typical saturation time below.

The cylinder saturation can be determined either by the TRANSEC monitoring system or by comparing water PPM in 2 oil samples (inlet & outlet).

A set of saturated cylinders can be removed and replaced while the transformer is online by new cylinders within 30 minutes.

Characteristics

| Typical time for extraction of 10 litres of water | |

|

New transformer water content <1% |

5 years |

| Old/Wet transformer water content >3% | 6-12 months |

| Moderately wet transformer water content = 2% | 2 years |

More than 15 years of successful experience

A TRANSEC unit was installed in November 2017 on 40 MVA General Electric 3 phases transformers in the Dammam region, Saudi Arabia. This 115kV/13.2kV transformer from the 1970s had reached a very high water content in the paper (above 5%) and needed urgent drying. Once installed, the TRANSEC started removing moisture from the oil immediately. It provided a positive effect on the breakdown voltage value. In a second step, water extracted from the paper as the oil dried out after a few weeks.

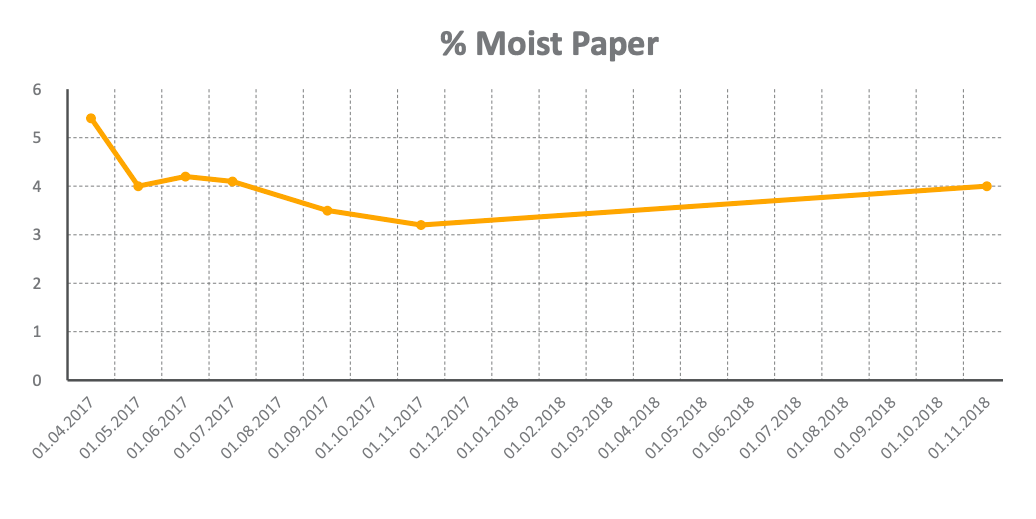

Over the 1st year, you can see on the 2 graphs that the PPM inflow and the water content are dropping.

Within that year, the water content in the paper went from 5% to about 3% (a much more acceptable level). We can also see that the PPM values of inflow and outflow during the second year of operation were almost matching, which is a sign of water saturation in the Transec unit. This is confirmed by the water content increasing again to 4% at the end of the second year. New ones then replace the saturated TRANSEC extraction cylinders to restart the filtering process.

They had extracted about 12 litres of water from that transformer within 1 year.